Project

ID-LIME

Manufacture and suitability of natural hydraulic limes as a binder in sustainable construction and restoration (ID-LIME)

definition and types

Lime

Binders (lime, gypsum or cement) have a binding function due to their adhesive and cohesive properties, capable of binding the aggregate grains together into a coherent mass (mortar). This function is achieved by the effect of chemical transformations that give rise to new compounds and which depend on the nature of the binder (aerial or hydraulic).

Lime is the binder most widely used by man throughout history. Depending on the raw material used and the chemical reactions that occur in its mass, lime can be of an aerial nature (it hardens in contact with air) or hydraulic (one part hardens in contact with air and the other part hardens in contact with water).

Air lime and hydraulic lime

Depending on the type of chemical transformations that lime produces when bound into a coherent mass such as mortar, it can be classified into two types: air lime and hydraulic lime.

Air lime

Air lime is a lime produced from the firing (around 900 ºC) of carbonate rocks, i.e. formed by more than 90% of carbonate minerals (e.g. calcite, calcite with low Mg content, dolomite, others), a stage of the lime process called calcination, which leads to the formation of a very reactive oxide that is quicklime.

This is transformed into hydroxide, called slaked (or hydrated) lime after the addition of water, a stage called slaking. The slaked lime, mixed with the aggregate and water, is transformed into the initial chemical compound (carbonate) after reacting with atmospheric CO2, a stage called carbonation. As a result of this chemical transformation, lime mortar becomes harder, more stable and less soluble than in its non-carbonated form. Each stage of the lime cycle is conditioned by some factors that are important to control in order to obtain a quality lime.

Hydraulic lime

Hydraulic limes are manufactured from a raw material that is normally calcareous, with a variable silica and alumina content, usually under the form of clays. These can vary from a maximum of 12% to obtain limes of moderate hydraulicity, to a maximum of 25% for limes of high hydraulicity, passing through an intermediate hydraulicity conferred by a clay content between 12 and 18%, to obtain a natural hydraulic lime.

The raw material is calcined in a kiln at 950 to 1200 ºC to obtain calcium oxide (quicklime) and calcium silicates and aluminates. A stoichiometric amount of water is added to this calcined product (exclusively industrial process) to only hydrate the calcium oxide, thus obtaining calcium hydroxide (slaked lime) and silicates (mainly C2S, bi-calcium silicates) and calcium aluminates. The latter, mixed with water in the mortar, react to form hydrated calcium silicates and aluminates, while the slaked lime carbonates, as in an air lime, to form calcium carbonate.

Hydrated silicates and aluminates are responsible for the hydraulic properties of mortars made with these limes, which are characterized by higher mechanical strengths than those of air lime mortars.

European regulations on

building limes

According to the European standard EN 459:1 2015, building limes are defined as follows:

CL90

Air lime of calcitic composition (CL, from “calcitic lime”), originating from a very pure limestone (CaO+MgO > 90%). Also colloquially called fat lime (MgO < 5%).

DL90

Magnesian lime (DL, from “dolomitic lime”), from a very pure limestone (CaO+MgO > 90%). Also colloquially called lean lime (MgO content can be < 30% or > 5%).

These two limes can be found on the market as quicklime (indicated by a final -Q) or slaked lime (indicated by an -S).

NHL, natural hydraulic lime (from “natural hydraulic lime”).

HL, hydraulic lime (from “hydraulic lime”).

These last two limes are found on the market with the indices 2, 3.5 and 5, according to the minimum mechanical strengths (value expressed in MPa) that mortars made with these limes and a standardized sand must reach after 28 days of setting.

These three indexes correspond, respectively, to a moderate, intermediate and high hydraulicity. At the same time, the European standard establishes the minimum content of free lime (expressed as Ca(OH)2) for these three limes as follows: ≥35 % for NHL2, ≥25 % for NHL3.5, and ≥15 % for NHL5.

Notwithstanding, European regulations do not consider the influence of variables such as the chemical-mineralogical composition of the raw material or the calcination and slaking conditions on the quality of NHL. This results in the existence of NHL on the market that, despite having the same index (2, 3.5 or 5), have different compositional, textural and physical characteristics.

Objectives of the project

The general objective of this project is to increase the knowledge on natural hydraulic lime, in order to promote its manufacture and its use as a sustainable binding material in new construction and renovation works, and in the restoration of architectural heritage.

To this end, the following specific objectives are proposed:

Suitability of the stone

To investigate the suitability of different stone types as raw materials for NHL production.

Knowing the manufacture

To comprehend the manufacturing process of NHL taking into account the different factors influencing the calcination and slaking steps.

Quality of NHL

o evaluate the quality of NHL according to chemical-mineralogical and textural criteria

Improving regulation

To promote an improvement in the specifications and conformity criteria contained in European regulations for NHL.

Project phases

Methodology

First phase

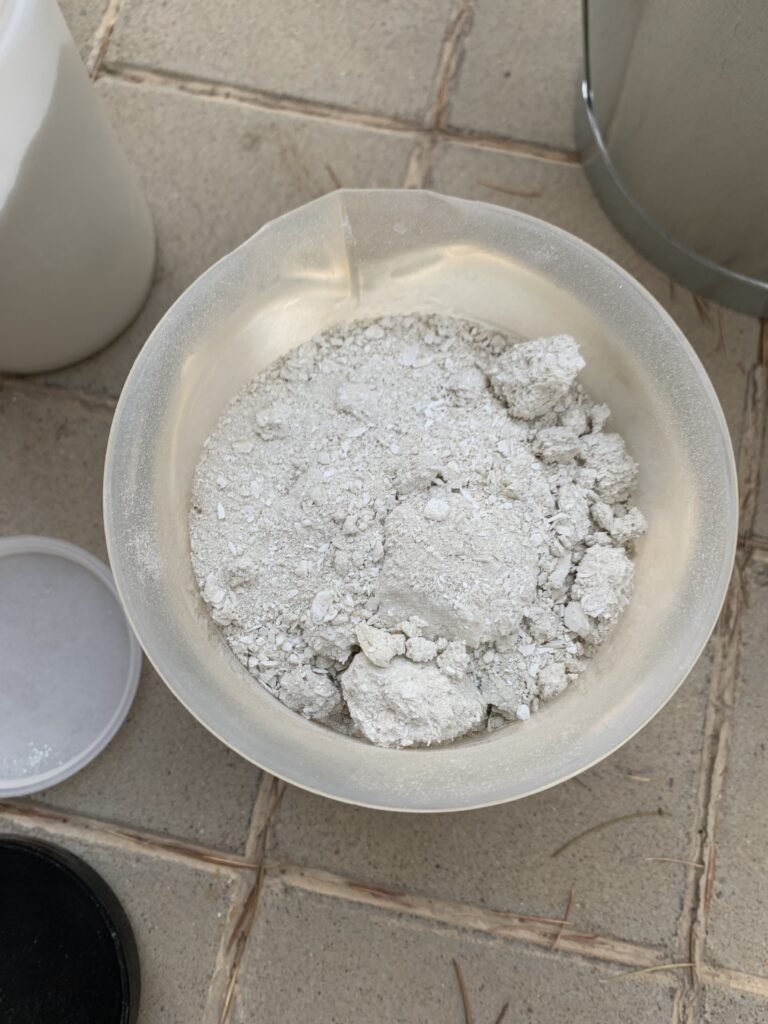

The first phase of this project focuses on the laboratory simulation of the manufacturing process of natural hydraulic limes, taking into account the factors that influence the different stages of manufacture, such as: 1) raw materials compositional and textural characteristics; 2) calcination conditions (temperature, duration and dwell time in the kiln); 3) slaking conditions (amount of water and duration). For a correct interpretation of the influence of these variables on the quality of the lime obtained, an exhaustive chemical-mineralogical and textural study is carried out on both the raw materials used and the products of each manufacturing step.

In parallel, in the first phase of the project, the existing natural hydraulic limes on the European market are characterised, in order to compare their chemical-mineralogical and textural characteristics with those of the NHLs manufactured in the laboratory. Around 15 types of commercial lime (NHL2, NHL3.5 and NHL5), manufactured in 5 different industrial plants are under study.

Second phase

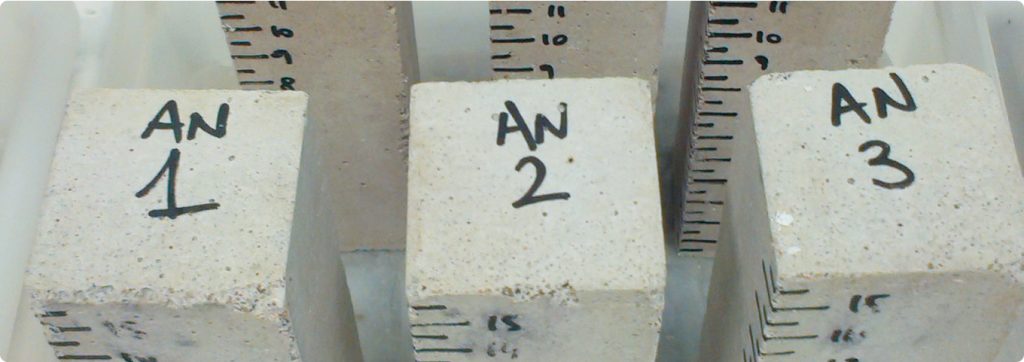

In the second phase of the project, the mortars produced with the NHLs manufactured in the laboratory are studied and compared with those made with the NHLs existing in the market. Mortars are prepared following the European regulations, with a CEN-NORMSAND standardised siliceous sand and a 1:3 lime-to-sand ratio (by weight). The properties of these mortars are studied during their fresh and hardening state, by means of chemical-mineralogical, textural and physical-mechanical techniques.

Scientific, technical and socio-economical impact

Thanks to the implementation of this research project, the following results are expected to be achieved:

-

In-depth knowledge of the manufacturing process of natural hydraulic lime and of the intrinsic (raw material) and extrinsic factors (calcination and slaking conditions) that affect its chemical and physical properties

-

Ability to discern possible differences between natural hydraulic limes belonging to the same group (2, 3.5 and 5).

-

Improvement of the European regulations concerning the specifications and conformity criteria of natural hydraulic limes.

-

Implementation of natural hydraulic lime kilns at local and/or national level.

The transversal nature of this project is based on its dual purpose of promoting the use of natural hydraulic lime as an alternative hydraulic binder to cement in restoration works, thus contributing to the safeguarding of architectural heritage, and at the same time encouraging the implementation of industrial processes with a lower environmental impact (compared to the cement industry), promoting the manufacture of a sustainable construction material.

This objective is possible thanks to the multidisciplinary approach that seeks to investigate, through chemical, mineralogical and physical techniques, new manufacturing technologies in the construction sector. It is also worth noting the cross-sectoral nature of this project, which will be expressed through collaborations with associations and private companies, which will benefit from the results of the project.

This project is framed within the challenge 5 “Climate change and the use of resources and raw materials” (of the National Plan for Scientific and Technical Research and Innovation of the Spanish Ministry of Economy, Industry and Competitiveness). Thanks to this project, knowledge about sustainable building materials and construction technologies will be expanded, a field in which there is much to be researched and developed in order to achieve a sustainable and resource-efficient Europe, which would also entail progress in innovation and entrepreneurship and, at the same time, the dissemination and consolidation of a new culture of sustainability within the European community.

This action will involve reducing CO2 emissions, one of the most important objectives proposed by the European Union for the next 25 years. According to the EU, “all sectors must contribute to the transition to a low-carbon economy, according to their technological and economic potential”. It is estimated that residential emissions can be almost completely reduced (by around 90% in 2050) if various actions are carried out on buildings, including “the renovation of old buildings to improve their energy efficiency”, which will have to be carried out using sustainable, efficient and durable materials, such as natural hydraulic lime mortars, as opposed to Portland cement mortars.

It is also worth highlighting the potential international impact of this project, the results of which could also be exploited in other countries that do not currently have natural hydraulic lime manufacturing plants.

The optimisation of the natural hydraulic lime manufacturing process will lead to the existence on the European market of NHL with more controlled compositional and textural characteristics, which can be classified in a more rigorous way. Due to its multidisciplinary approach and degree of innovation, this project proposes a novel but absolutely necessary research for the Architectural Heritage, whose conservation is frequently broken by the incorrect use of building materials that are not compatible with historical materials. This will have a great impact on the sector of restoration of historical buildings, because more suitable and compatible hydraulic restoration mortars will be available. Therefore, the results of this project will also contribute to the conservation of the European Architectural Heritage.

PARTICIPANTS

Research Team

Anna Arizzi (IP)

Profa. Hired Dr. indefinite. Department of Mineralogy and Petrology, UGR

Giuseppe Cultrone

University Professor, Department of Mineralogy and Petrology UGR.

Carolina Cardell Fernández

Lecturer, Department of Mineralogy and Petrology, UGR

María Lourdes Gutiérrez Carrillo

Lecturer, Department of Architectural Constructions, UGR.

María Gracia Bagur González

University Professor, Department of Analytical Chemistry, UGR

Maja Urosevic

PhD in Earth Sciences, PTA in the Department of Mineralogy and Petrology, UGR.

Salvador Morales Ruano

Professor at the University of Granada, UGR.

Work team

Clara Parra Fernández

PhD student, FPI scholarship holder, Department of Mineralogy and Petrology, UGR

Laura Crespo López

PhD in Earth Sciences, Contracted at CIC-UGR.

Publications and conference proceedings derived from ID-LIME project

These are the featured publications from 2022 to 2024t

- Parra-Fernández C., Porta Igual J.A., Arizzi A., Morales Ruano S., Cultrone G.

- Porta Igual J.A., Arizzi A., Sebastián Pardo E.M. Historical and production study of the cement and hydraulic lime factory Nª Señora de los Dolores in Atarfe, Granada (Spain) Proceedings of Historic Mortars Cconference, HMC2022. Ljubljana, Slovenia, (2022).

- Galdó-Ceballos E., Gutiérrez-Carrillo M.L., Arizzi A. Atlas of lime kilns in the Spanish territory: settlement, constructive typology and production process of lime as a historic material Proceedings of Historic Mortars Cconference, HMC2022. Ljubljana, Slovenia, (2022).

- Arizzi A. Learning from Historic Mortars: Studies on Lime Manufacturing and Fresco conservation Ponencia invitada en 1st International Conference with workshop Science for Conservation of the Danube Limes, Belgrado (Serbia), 27 Junio-1 Julio 2022. Actas de Congreso “Science for Conservation of the Danube Limes” Ed. Korak M., Institute of Archaeology, pp. 88-90. ISBN: 978-86-6439-072-9 (2022).

- Arizzi A. Studying the durability of lime-based mortars: standardised, stochastic, and in-situ weathering tests RILEM proceedings of the workshop “Lime based materials for repairing historic Structures”, Thessaloniki, Grecia, (2022).

- Morales Ruano S., Arizzi A., Cultrone G., Parra Fernández C., Bagur González M.G Presentación de póster en XXXIX Reunión de la Sociedad Española de Mineralogía en Baeza (España). Macla, 26, pp. 132-133 (2022). ISBN: 2659-9864.

- Urosevic M., Jiménez-Desmond D., Arizzi, A., Pozo-Antonio JS., Moreno Prieto C., Vila Oblitas M. Analysis of pigments and mortars from the wall paintings of the Roman archaeological site of Las Dunas (San Pedro de Alcántara, Málaga S Spain) Journal of Archaeological Sciences: Reports, 52 (2023) 104280

- Parra-Fernández C., Arizzi A. The properties of natural hydraulic lime as a sustainable building material II Congreso Internacional sobre Innovación y Sostenibilidad en la Vivienda Social, ISVIS 2023, Granada (2023).

- Parra-Fernández C., Arizzi A. Optimización del proceso de fabricación de la cal hidráulica natural de cara a su uso en restauración del Patrimonio Arquitectónico I Jornadas de Investigadores Junior en Patrimonio (JIP 2023), Madrid. Book of Proceedings JIP2023, pp. 54-55 (2023).

- Parra-Fernández C., Arizzi A. An experimental study on the slaking process of natural hydraulic lime Accepted for presentation during SubLime Conference, Funchal, Madeira, Portugal (2024).

- Parra-Fernández C., Arizzi A., Secco M., Cultrone G. The manufacture of natural hydraulic limes: influence of raw materials’ composition, calcination and slaking in the crystal-chemical properties of binders Under review in Cement and Concrete Research (2024).